Daze wrote:

Daze wrote:

TKOPerformance wrote:

TKOPerformance wrote:

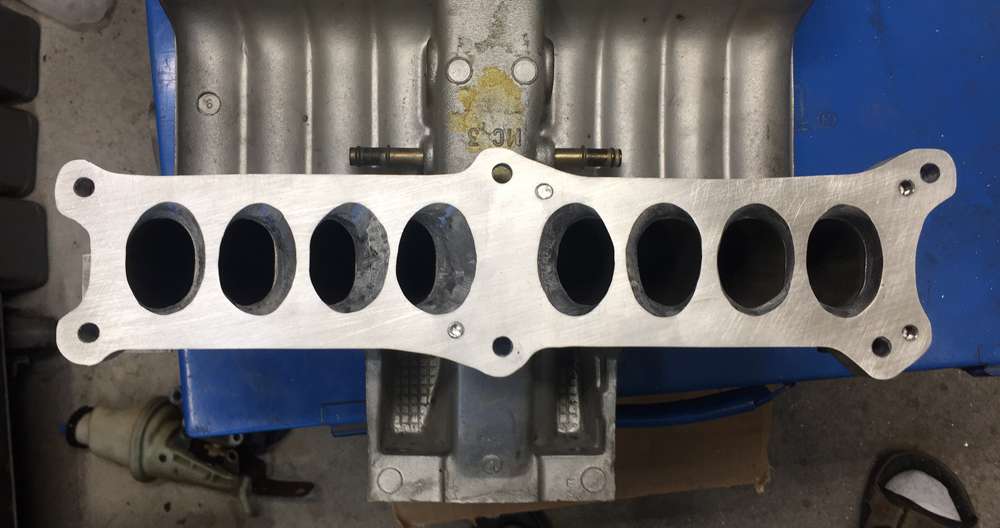

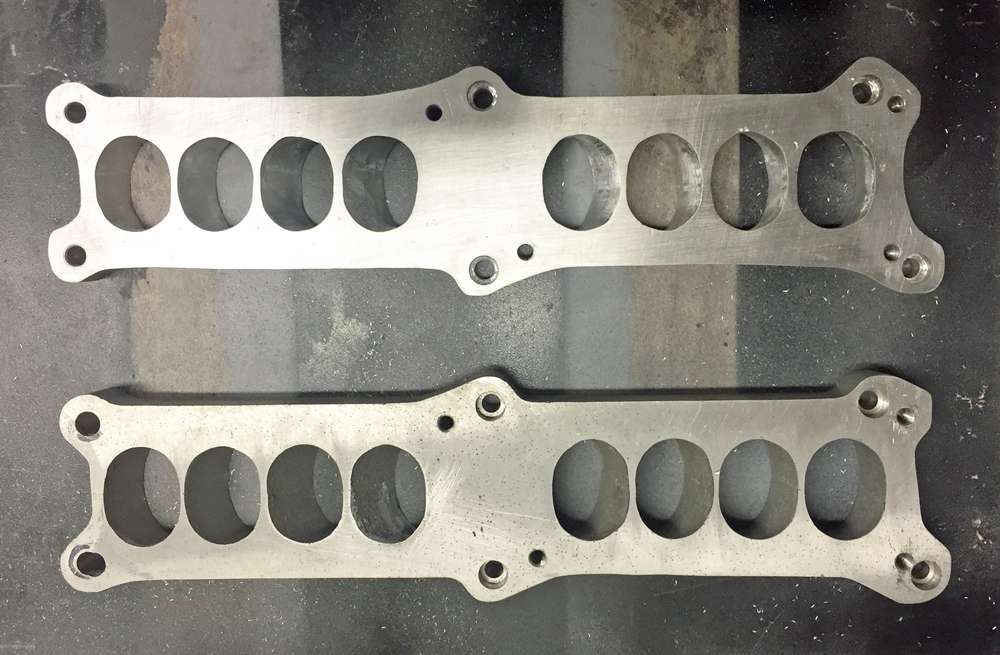

An adapter is certainly a work around. I suppose it depends on what you want out of the engine. For a stock type application its probably going to be okay. For anything else I worry that some of the passages are half occluded and the flow cylinder to cylinder is going to be different. I think I'd look to build a new upper if I wanted the engine to make a lot of power. It would be fairly easy to copy the way a tubular GT40 is done if you can weld aluminum.

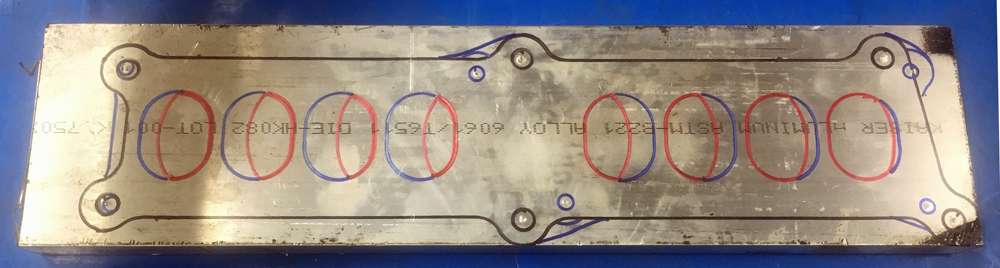

I don’t agree. Once the adapter is done it will be a smooth flow and equal opening size across all 8 cylinders. I think little to no power would be lost even on a performance engine. In fact the power limitations are probably the OEM pieces. I will concede that having to make a slight turn could reduce airflow slightly however it is so minimal that you’d have to be running hugely high RPMs and a much higher displacement to even see noticeable number changes. In my case it should not matter anyway because it’s a stock rotating assembly and the only the only power adders are aluminum heads and headers.

I thought about making a custom upper and there is no EASY way way to do it and still have roughly equal runner length. Tubular upper intake’s are offset cylinder to cylinder so a person can get around to weld the tubes to the flange. There is not enough space between where the tubes would go on the truck pattern and if you don’t go tubular the only other option is an open plenum just dumping in to all 8 ports and there’s definitely no equal flow at that point. I really do think the adapter is the most elegant solution to this problem.

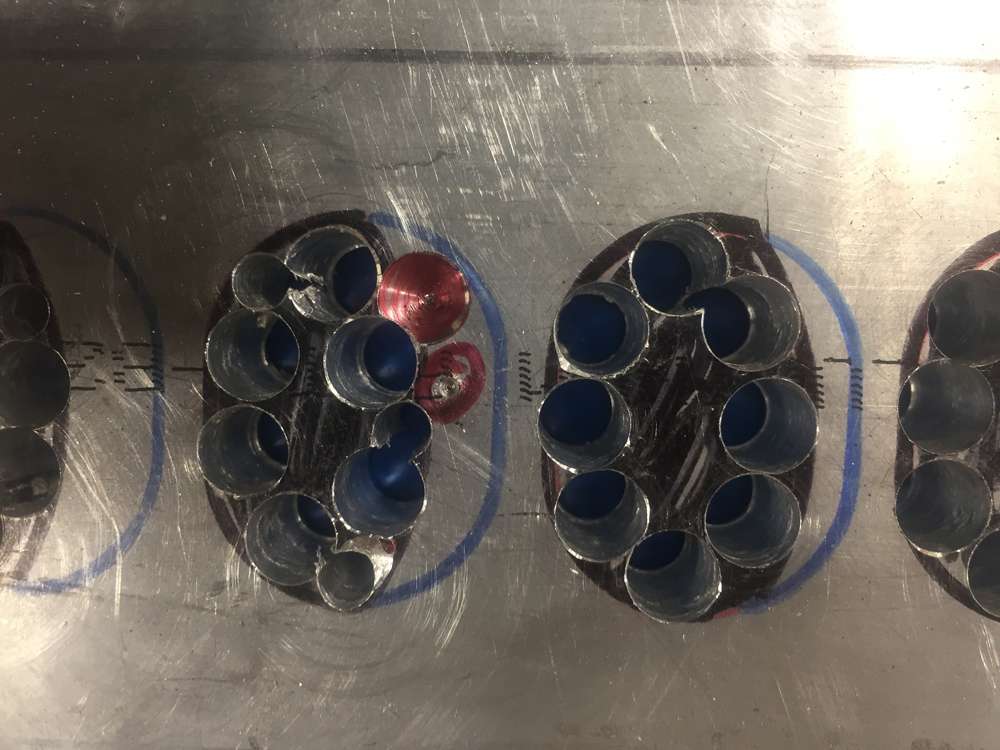

Equalizing cross section area isn't the same thing as equalizing flow. Some of those ports are pretty severely offset. Sure, you can cut partway in one pattern on one side, partway on the other on the other side, and blend the transition in the middle, but air doesn't care about cross section it cares about changing direction. You're still asking it to make a dogleg of varying degrees in varying cylinders. If the intake were pressurized it wouldn't much matter, but when relying only on the vacuum produced by the cylinders its going to lose boundary layer adhesion and spall, creating turbulence and hindering flow. Were it doing this uniformly it wouldn't matter, my concern is that the best cylinder almost perfectly lines up, but the worst is less than half aligned.

How much difference will it make, its hard to say without very sophisticated computer modeling, a flow bench, or running the engine with EGT probes in each header pipe. In the end, it may seem to run fine, but there's no way to tell it really is. EFI covers a lot of sins.

As far as making a new upper, you would weld the tubes on the underside of the flange that bolts to the lower intake, not the top. The tubes could be right next to each other and it wouldn't matter. Then the tubes go into a plenum tapered to the TB flange. You're worrying too much about equal length. The plenum is the equalizer. Its not a wet intake where you have to worry about the fuel falling out of suspension as it reaches the ends of the plenum.

On the cheap try dipping your burrs in ATF. It keeps aluminum from sticking to the burs. Also using single cut burs keeps them from loading up as much. Double cut work good for steel and iron, but not for aluminum; they are too prone to loading up.

1

1

Nos681 wrote:

Nos681 wrote: