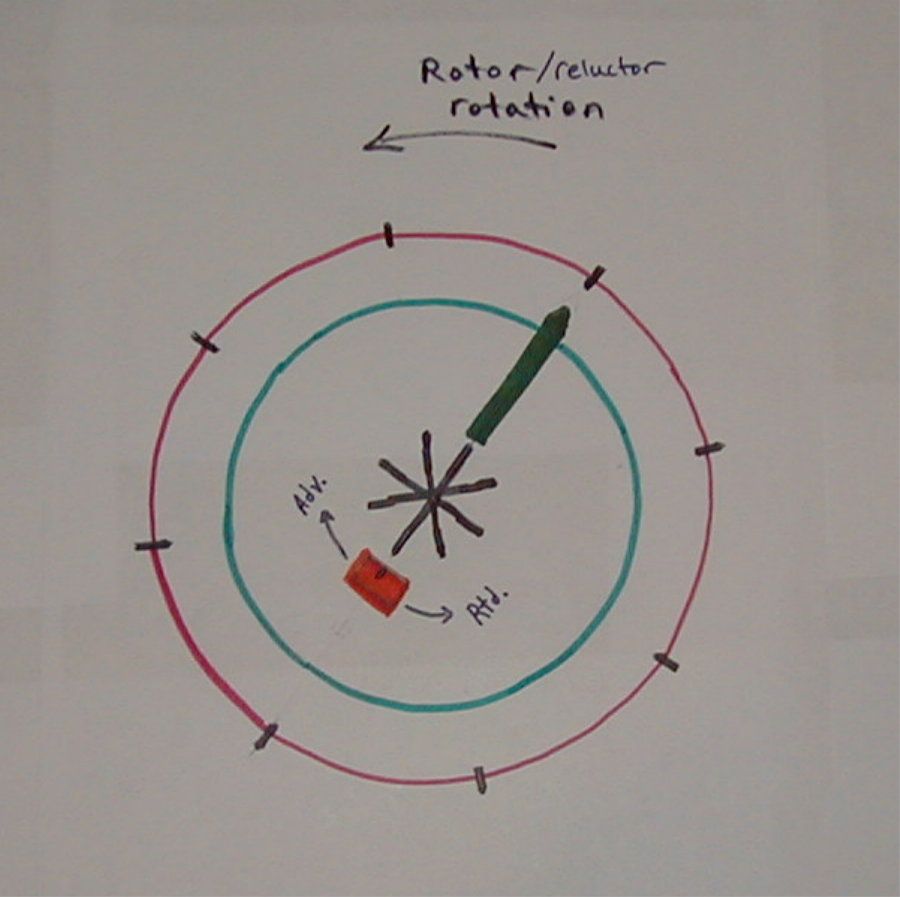

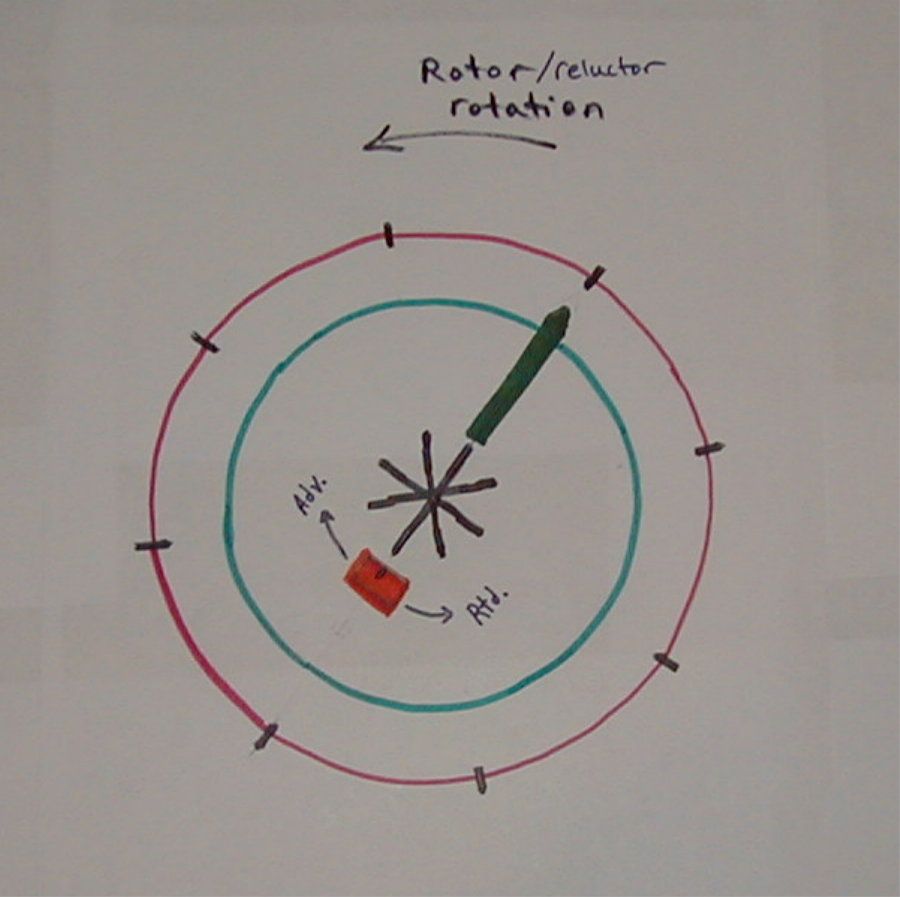

Red circle = dist cap, black marks represent the terminals.

blue circle = distributor

green arrow = rotor

black asterisk = 8 point reluctor wheel

orange block = mag pickup/points trigger

Rotor and reluctor rotate counter clockwise and are "fixed" to each other, one does not move more or less than the other in degrees of rotation, period. Every 45* of rotation, one reluctor vane lines up with the mag pickup sending a spark across the rotor tip to a cap terminal.

Consider the drawing set at "base" timing (8*, 10*, 14*, whatever....it does not matter for this explanation). From this point, the dist body and cap are bolted down and cannot move. In a perfect world, at this point, the pickup, reluctor, rotor tip, and cap terminal are all in perfect alignment. In the real world, due to things like mass produced parts, worn parts, machining error, etc, the alignment can be "off" slightly. A couple of degrees isn't much of a problem, but "all" degrees that it is "off" are cumulative. The vacuum adv moves the pickup in a clockwise direction, advancing the timing, sending the "fire" signal sooner, keeping in mind that to trigger the pickup the reluctor has to be aligned with it, and the dist and cap are "fixed" and the reluctor and rotor are fixed, so the spark will occur some degrees before the rotor tip and cap terminal are in "perfect" alignment. Add in any component missalignment and some mechanical advance (could be a little, could be alot depending on how much the advance plate allows and the spring strength on the counter weights) and you could end up with the spark occuring far from the cap terminal. Electricity follows the path of least resistence, it could be the appropriate terminal, or the one before, or a little to both, or wherever. The effort of "phasing" the distributor, either through an adjustable rotor tip or adjustable pickup, is to get the spark signal firing toward the "lagging" edge of the cap terminal at base timing so that when the "advances" kick in the spark will fall on the "leading" edge of the cap terminal and not off in open space.

MarkinSC wrote:

MarkinSC wrote: