A tandem Ford MC with a constant bore diameter throughout (same size bore on the secondary side as the primary side) will produce a given amount of output pressure for a given amount of input pressure applied on the brake pedal. This will be true whether it's a drum/drum, disc/drum or disc/disc MC. In simple terms, the MC is just a manually-actuated hydraulic pump.

While pressure and flow are related, they are still independent of each other. There's a primary and secondary seal on each of the primary and secondary MC pistons. The distance between the seals on each piston determines the amount of volume the pistons will displace when the brakes are applied, for a given amount of pedal stroke.

Some examples in the differences in the distance between the MC piston seals seen here ('84-'90 1-1/8" Mk VII/SVO MC on the left, 1-3/16" primary piston and 13/16" secondary piston on '87-'93 5.0L Mustang GT/LX MC at top right and a '99-'04 V6 Mustang 1.00" bore MC at bottom right).

Typically, a 'conventional' cast iron Ford disc/drum MC will have a larger primary reservoir than the secondary reservoir. A typical, 'conventional' cast iron drum/drum MC will have equal sized reservoirs. Brakes are the most important system of any vehicle and requires a good deal of knowledge in how the various components work, if you're changing things up.

It is possible to use a disc/drum or a disc/disc MC on a drum/drum or disc/drum vehicle but, it's never a good idea to use a drum/drum MC on a disc/drum or disc/disc equipped vehicle. The reason is in the size of the primary brake reservoir of the drum/drum MC. A drum/drum MC will not have enough fluid reserve to support the front brakes, once the pads and the rotor friction surfaces wear down. As these items wear, the pistons have to move outward to compensate for this wear.

This means the front pistons will pull more fluid volume from the primary MC reservoir to fill the void that would be left in the calipers and is why the primary reservoir on the disc/drum or disc/disc MC is larger than the drum/drum MC.

Typical, 'conventional' Ford cast iron drum/drum MC.

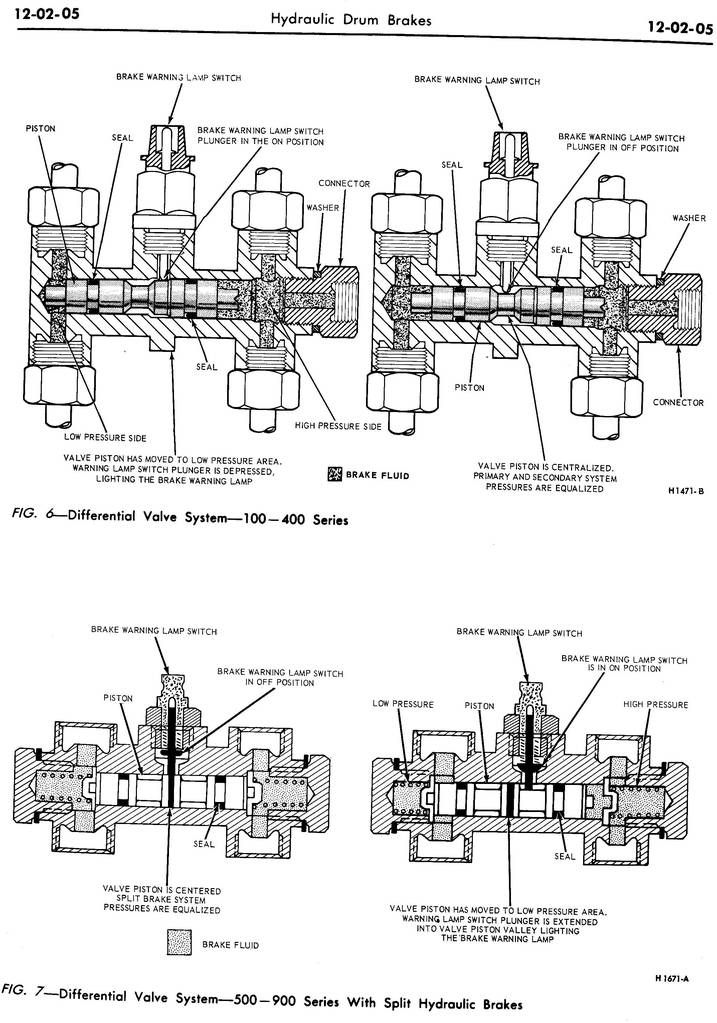

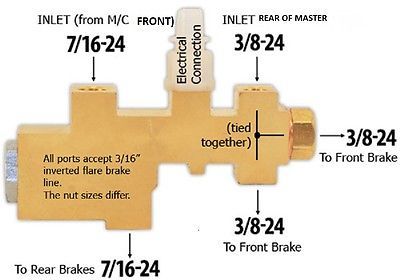

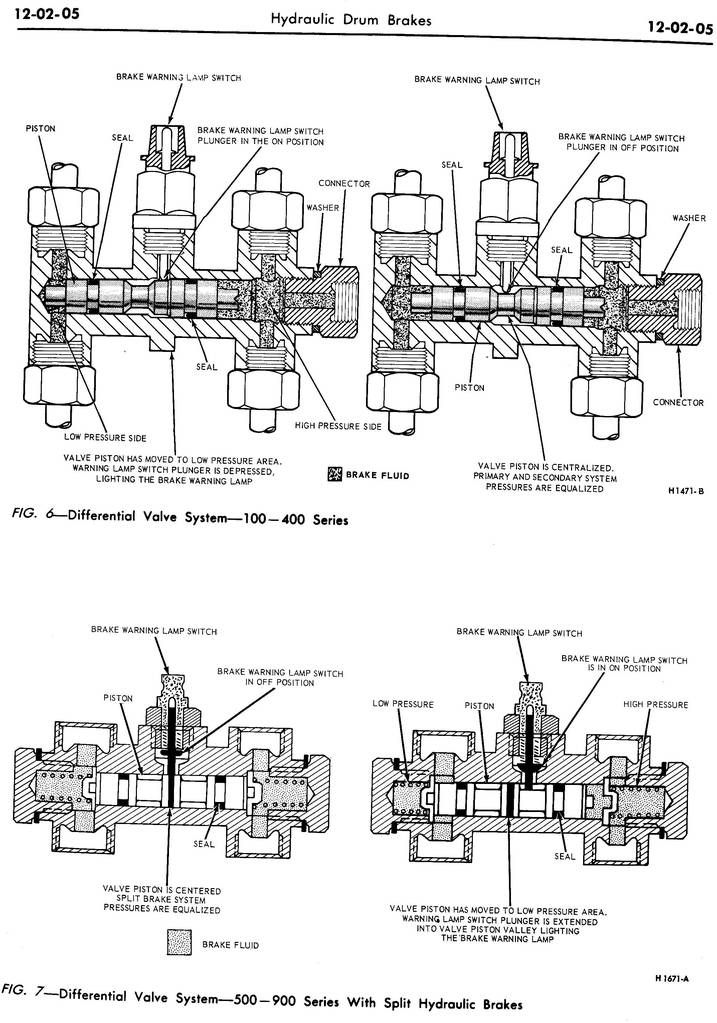

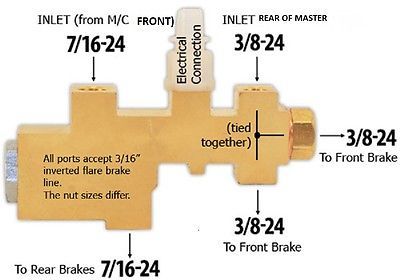

The standard hard brake line diameter in these vehicles is 3/16" (outside dimension). The passages of the MC, brake valve, calipers/wheel cylinders and the flexible hoses are all designed to flow accordingly to this dimension. In a drum/drum application from '67-onward, the brake valve used was a Pressure Differential Valve. It sensed for an imbalance in pressures between the primary (front) and secondary (rear) brake circuits. If there was a brake component, hard line or flexible brake line failure, where there was a loss of brake fluid --and thus a loss in brake pressure in one of the circuits, the valve spool inside the PDV would shift, close the contacts of a switch mounted in the valve body and illuminate a brake warning light on the dash.

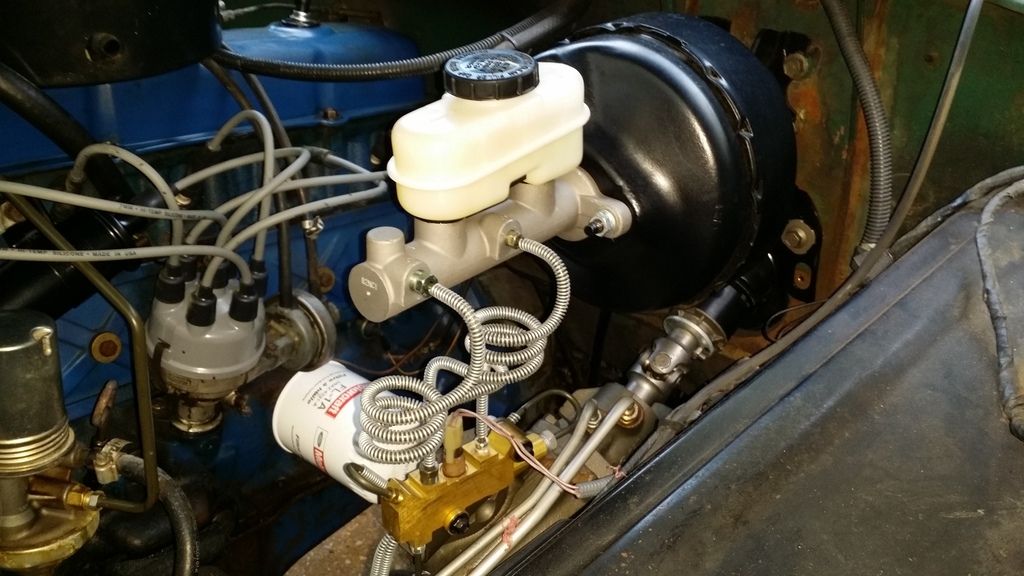

Inner workings of a pressure differential valve (this valve [upper half of photo] is for a '67-'72 Ford truck. It's configured and works just the same as a drum/drum PDV on a '67-up Mustang).

'67-'69 Mustangs with factory front discs and drums on the rear got a PDV along with an external proportioning valve. These two brake functions weren't integrated into a common brake valve assembly until 1970.

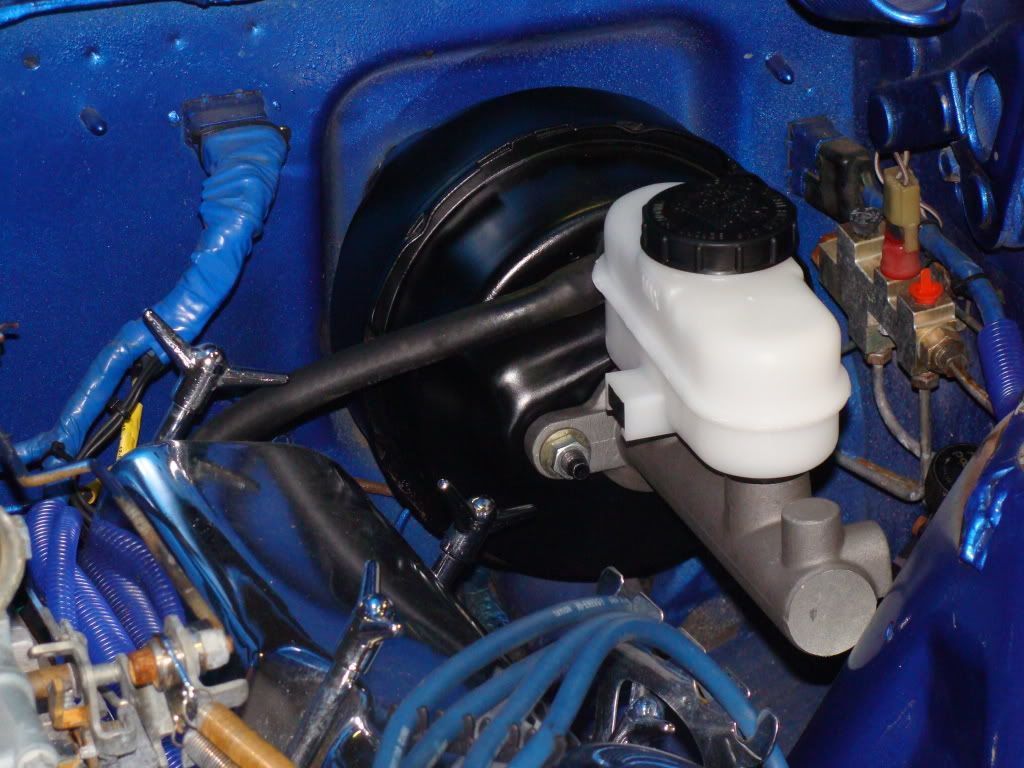

'68/'69 Mustang disc/drum brake valve (PDV with external proportioning valve).

1970-later factory disc/drum equipped Mustangs would have had an integrated PDV/proportioning valve like this. The proportioning pressure is preset and non-adjustable with this valve.

A proportioning valve isn't active everytime you step on the brakes. --during normal braking, it doesn't do anything. It only becomes active when the pressure rise inside the brake system becomes sufficient enough to act on the annular ends of the proportioning poppet valve to force it to overcome the tension of the spring and then to move the poppet valve over to begin reducing the rate of pressure rise to the rear brakes, relative to the pressure acting on the front brakes. Proportioning valves don't limit the amount of pressure to the rear brakes. They only slow down the rate of pressure rise to the rear brakes, proportional to the pressure acting on the front brakes.

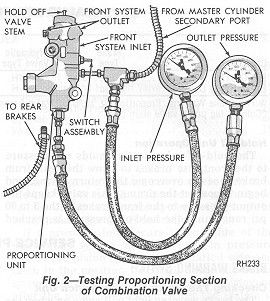

Manually-adjustable proportioning valves get installed on a lot of vehicles but, I suspect very few are actually set with the use of brake pressure gauges. Turning the knob and making some stops, repeating the process, equates to nothing more than a WAG at what the M-A proportioning valve is actually being set to, without the use of pressure guages. If you do have a set of pressure guages, you first have to know what the minimum, preliminary pressure setting and percentage of reduction is that you're trying to set the M-A proportioning valve to. --for an early Mustang, that would be 300 PSI @ 50% reduction in the rate of pressure rise of the rear brakes, in proportion to the fronts. Without a set of guages, you would most likely overshoot or undershoot this mark. M-A proportioning valves are also not DOT approved for highway use.

1 of 1

1 of 1

ultrastang wrote:

ultrastang wrote: