rpm wrote:

rpm wrote:

Damn nice work Daze! Do you have any pics of the work piece in the lathe. I'm interested in how you chucked it up.

Thanks!!

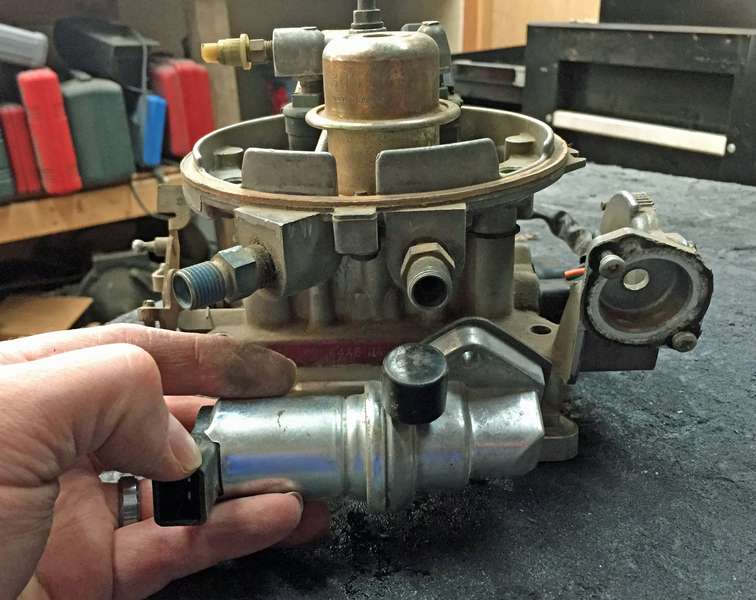

I didn't take any pictures when I modified the unit but it only took me a minute to pull it apart and chuck it up in the lathe to show you how I did it.

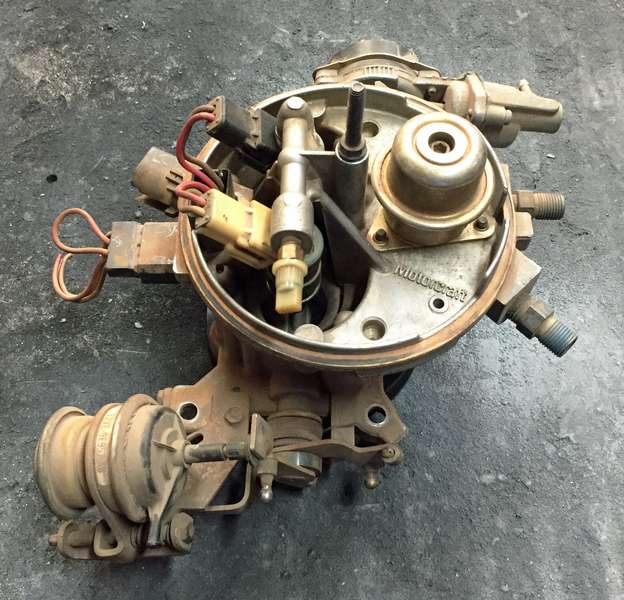

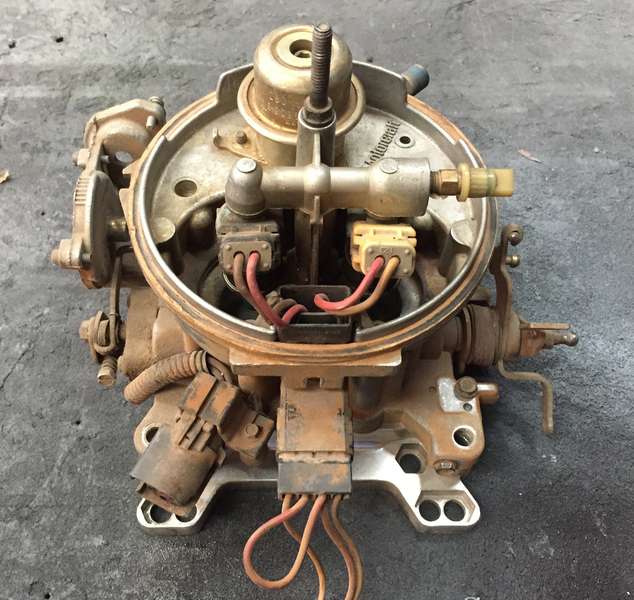

Like I said above the bore at the butterflies was 1.56" but then there was a lip (not even a smooth transition) where it went down to the smaller size. Not sure why Ford did that there were two versions of this CFI and one was necked down and the other wasn't.

In this picture you can see a distinct line where the original darker bore meets my enlarged bore.

To do the machine work I simply used a reverse hold on the butterfly part of the bore and then an internal cutting tool (boring bar) to enlarge things.

Raymond_B wrote:

Raymond_B wrote:

How much HP do you think those injectors and the new larger airflow bore can support? I know you're not going for crazy high #'s, but I am just curious.

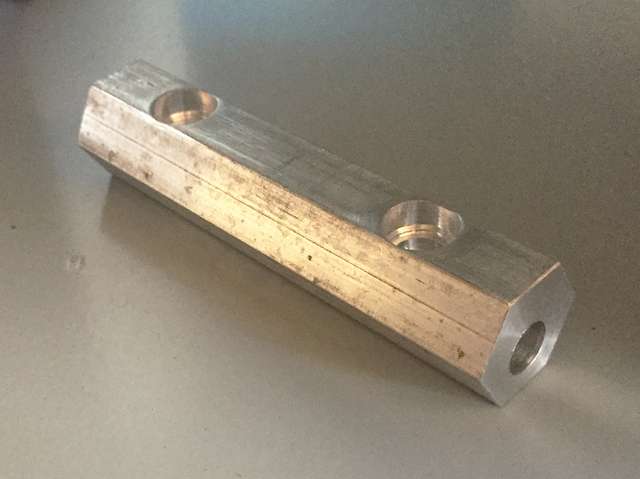

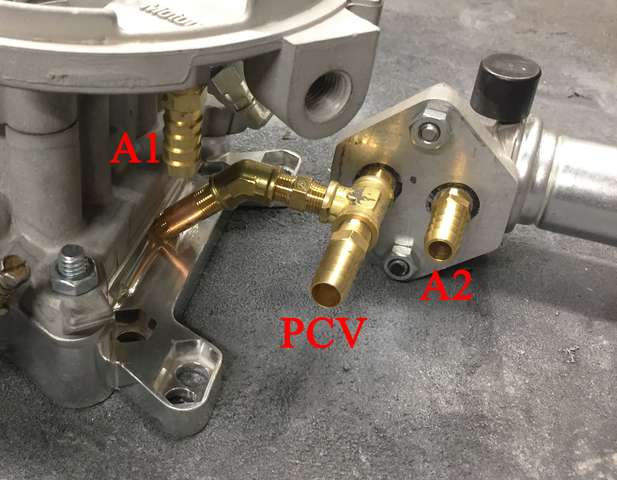

Its going on a 351W The rule of thumb with injectors is you want the sum total of Lbs/Hr to be 1/2 of max horse power assuming you will not be running it at max most of the time. The extra injectors are 46 each (not the ones in the picture those are sacrificial 18s) and the two injectors actually mounting in the unit are 52 each for a total of 196. That means I am good to a max HP of 392. According to my desktop dyno (which tends to be a little high) this engine should produce at most 371 HP at 6000 RPMs so I am good for fuel. As to air flow the new enlarged bore is the same as most 2 barrel carburetors at the butterflies but carburetors neck down with a custom shape to create the venturi effect so it should flow better than a stock 2-barrel. I know engines as big a 390s have gotten OEM 2-barrel carbs and run well so I think my airflow will be sufficient. I know I won't be maximizing HP but I probably won't spend much time running it above 4500 RPM so it shouldn't be and issue and the 2-barrel setup should be good for low end torque with is the goal of this build anyway.

1 of 1

1 of 1

rpm wrote:

rpm wrote: