I’ve spent close to 2 hours on the phone with MDL and Tilton. They both said close to the same thing on all accounts. Like the collar shouldn’t have adjusted inward that far that soon. Spent a lot of time discussing how I set the clearance between the bearing and the clutch fingers to make sure I did it right to begin with. Sent them both a bunch of pictures of how it went together and how I found it after the fact. I also got to confirm that the runout was within spec for the transmission into the scatter sheild.

MDL wasn’t a fan of Centerforce when I ordered the kit in 2013 for the 5 speed. I got the same story on the weights interfering with the bearing. Mine shows no signs of contact. They also talked about the Tilton TO bearing not liking the how the weights caused varying clamping force depending on RPM.

MDL has made some changes to the kit, like a .500” shim at the transmission isolation mount to raise the back end up to get the drive line angle right. I asked the questions before buying the kit in 2013. Will I have to cut the trans tunnel, no. Will the drive line angle be right, yes. I did test fit the transmission before body work was complete. I didn’t check the angle though. Shame on me for doing half of the work. My boss talks about “trust but verify”, it works for this.

If the angle isn’t right when I get it back together, I don’t think I have the room to install .500’ worth of spacer. That should put me in contact with the tunnel. I will have to install the angles on the rearend to roll the pinion.

Neither was overjoyed with the idea of staking the threads on the collar to prevent or slow adjustment, but understood if I went that route. The Tilton rep did offer up using urethane on the threads to really slow the adjusting ability.

Tilton did ask about tire age when I mentioned having them re- balanced. Could they have flat spots?? At just over a year old, I don’t really think so.

After all the talk, there’s no smoking gun on what caused the collar to adjust inward other than speculation on the vibration!!

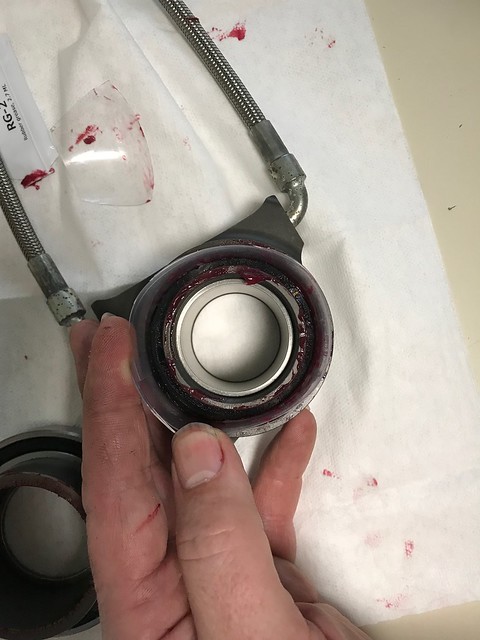

A new seal kit for the TO bearing is coming, it should be here on Friday. The drive shaft checked out on balance, it’s not the problem. I will get the tires to the shop this weekend.

Contrary to what I said above, I am looking into a new clutch. I found several stories about the weights on a Centerforce causing vibration issues. As I was laying under the car talking with Tech support, I noticed one of the counter weights hanging below the others on the high side of the circle! I pushed it up and it stayed, but for how long. I can only wonder if that’s the problem. The down side to this is I think I pushed in the clutch at speed and the vibration continued. I didn’t get enough time to troubleshoot before the TO bearing failed.

Still looking to get it to the Bash. At this point, Sheryl has little faith in it and wants to trailer it up there. She doesn’t want to be stranded on side of the road. I can’t say I blame her

Last edited by Bolted to Floor (9/05/2018 11:18 PM)

1 of 1

1 of 1

50vert wrote:

50vert wrote: