And hopefully without having to eat the spring or dig it out of the wall.

First buy the best kits you can find. That way you'll only be partially disapointed. More on that later.

Disassembly:

The hinge pins and door-stop pin should drive out easily with 1/4" drift and a reasonable sized whammer. You may want to apply some penitrating oil over nigtht.

But the roller pin is pressed into a blind hole and requires a little thinking. The obvious solution, which didn't occur to me until I asked Mustang Steve, is fairly simple really. Just weld a 5/16" bolt to the head of that pin and by placing a deep socket or other properly sized piece of tubing over the bolt/pin, you can pull the pin by tightning a nut down against a washer on top of the tube. Simple puller.

Reassembly after clean-up/paint

The first pin to reset is the roller pin, and here's where you may be disapointed with your new rebuild kit. The roller pin and door-stop pin that came with mine were so soft that part of the new pin rolled up, out of the hole and caused the roller to bind...seriously.

The solution was to weld/pull the new pin. Cut the welded-on bolt off of the old pin and reuse the original pin. It was worn a bit so I turned it 180 degrees from it's original orientation.

Steve recommends grinding about 1/16" off of the length of the new roller. This will allow you to get a little lube under the pin head and maybe between the pin and the roller. Something that was nearly impossible on the original setup.

Next you can press in the door stop pin and again, you may want to reuse the original rather than fight the soft repop pin...I did.

Now drive out the old bushing using a drift. A long tapered 1/8" seems to work well as it will engage the edge of the old bushing down inside the hole.

Tap in the new bushings and apply a light coat of lube. I like white lithium here.

The new repop hinge pin goes in easily so I was able to use the new ones here. I do have to wonder how long they will last considering they are much softer than the originals.

Now for the fun part: Installing the new springs

Compressing and holding compressed springs can be a challenge. I was reminded of the last Model A shifter spring I had to install compressed. It missed me but just barely. And I was amazed that it would put that big of a hole in sheetrock...from that far away.

Now, granted, Mustang door hinge springs are a lot smaller than a Model A shifter spring but they still could have a lot of energy if one got loose. The standard accepted method for installing compressed springs (as least as far as I know, unless you own a fancy compressor) is to compress the spring with some sort of squeezer...like, maybe a vice, and then tie the coils in three or four places with wire. Then you release the vice and install the compressed spring, cut the wire, and everything is jake. Well, I kept thinking about that Model A spring and came up with a slightly better way, I think.

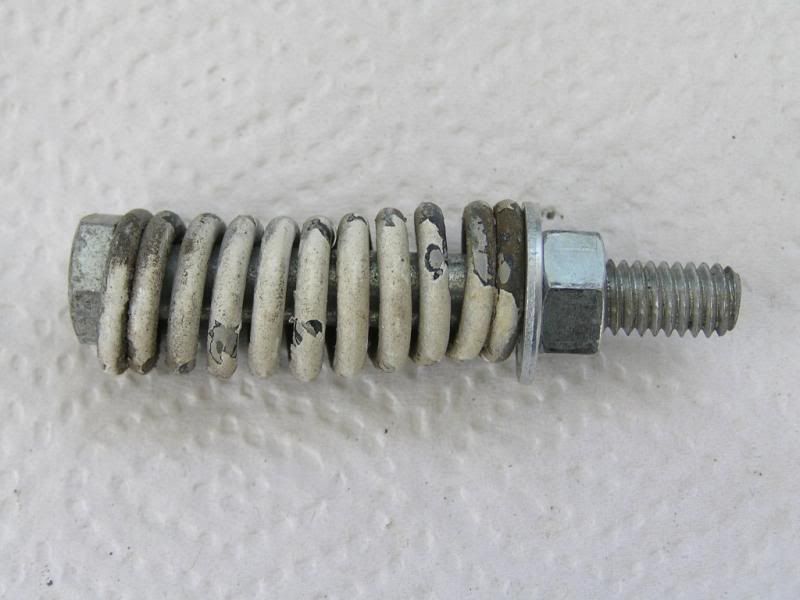

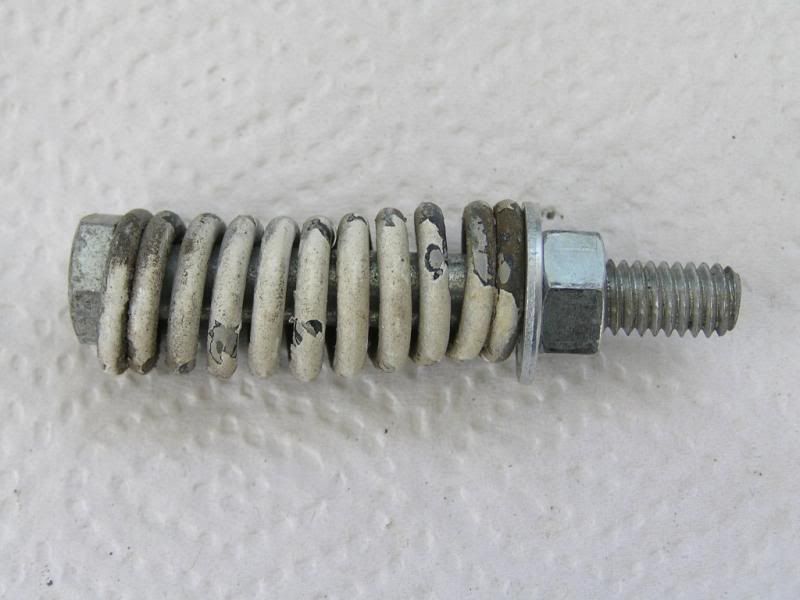

First use a 5/16" X 2 1/2" bolt to compress the spring.

Sorry...I took pix after everything was done so I had to use the old mangy spring for the pix.

Then make a compressed spring holder as follows:

Find a piece of tubing that has an ID just bigger than the diameter of the spring, cut off a piece about 1" long and weld a 5/16 flat washer to each end of that piece of tubing.

Split the assembly length-wise and do a little massaging and grinding to the washer halves so they are sort of going in the same direction as the spring coils.

Put the two pieces around the compressed spring, get them more-or-less lined up with the spaces between the compressed coils and clamp them tight with a pair of Vice-Grips.

Now, release the 5/16 nut, get the the assembly positioned into the space in the door hinge, and release the Vice-Grip. Sproing...everything perfect. No broken glasses, no lost springs, no holes in the sheetrock.

Hope this helps or at least saves some frustration.

BB

1 of 1

1 of 1