Mustangs prior to 1967 had a distribution block --essentially nothing more than a Tee to split the brake line from the single reservoir MC off to the front and rear brake circuits. One line rupture or component failure, where there's a loss of brake fluid/pressure in the system, means ALL brakes on the vehicle fail.

1967 was the first year for a tandem MC that split the front brake circuit, independently, from the rear brake circuit. A failure of the rear brakes does not disable the front brakes and vise-versa, although, braking ability will be greatly reduced in this scenario. On a 4-wheel drum brake setup, the only brake valve in the system was a pressure differential valve. It had a pressure differential valve spool inside and a nylon electrical switch sticking out of the valve body assembly. --'67 had a 1-wire connection on the PDV switch. '68 and beyond had a 2-wire conection but, the two prongs on the '68-up switch were tied together and, electrically, are at the same potential.

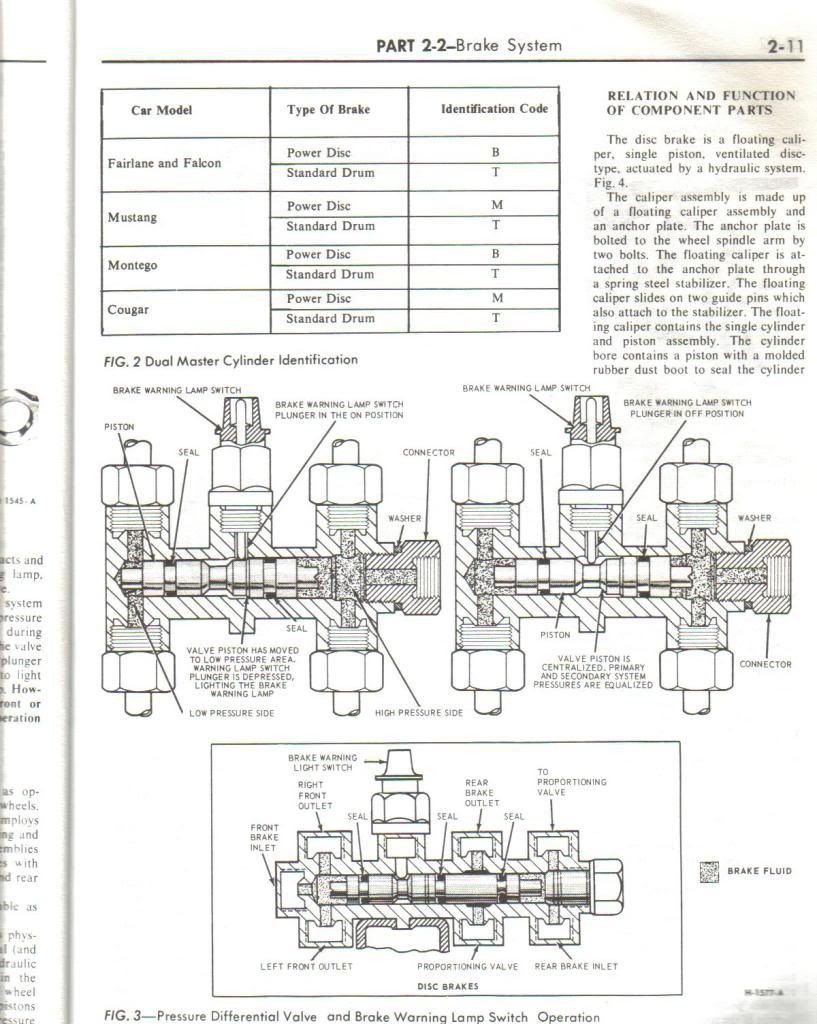

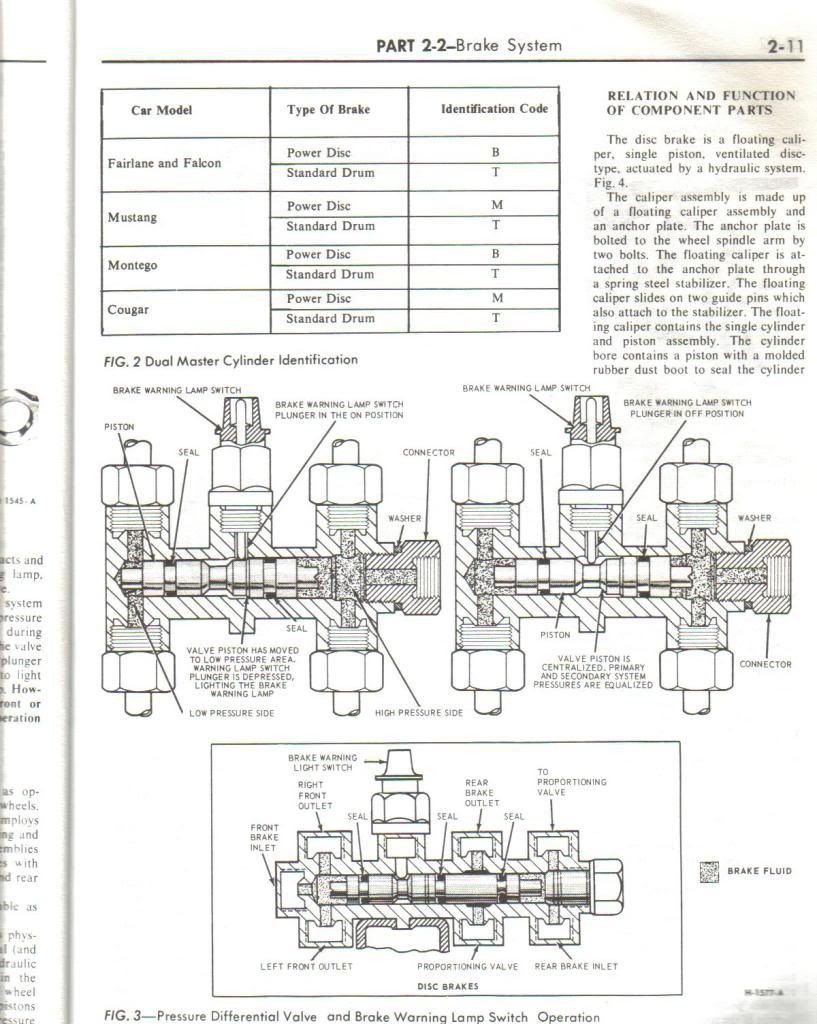

As long as system pressures (front and rear) are equal, the spool remains centered and the brake warning light will remain off. If there was an imbalance in system pressures --if there's a rear brake line rupture or wheel cylinder/caliper failure, etc., for example, the higher system pressure of the front brake circuit will push on the end of the pressure differential valve spool and shift the spool over to the (lower) pressure failed side.

The PDV spool is hour glass-shaped in the center. The plunger on the switch resides in this detent when the spool is centered an thus the contacts of the switch are open so, the warning light does not illuminate. When there's a failure, a shift in system pressures moves the spool over and the switch plunger rides up a ramp on the valve spool. This pushes the plunger in which closes the switch contacts. This completes an electrical path to ground through the body of the valve and through the chassis. This in turn lights up the brake warning light on the dash.

Some information suggests the shift of the valve spool cuts off fluid flow to the failed side. Some suggests it just turns the warning light on to alert the driver that there's a problem with the brake system.

So long as the OEM brake valve is a pressure differential valve and not an OEM disc/drum pressure differential/proportioning valve, a manually-adjustable proportioning valve can be plumbed inline between the PDV and the rear brake circuit without any other changes.

If an OEM combination valve (designed for discs/drums) is used with a manually-adjustable proportioning valve, the OEM proportioning valve components will have to be removed (gutted) from the OEM brake valve body so that there aren't TWO proportioning valves battling each other for control over the rear brakes.

Internal workings of the pressure differential valve.

Last edited by ultrastang (12/30/2015 7:42 PM)

1 of 1

1 of 1

airdrew99 wrote:

airdrew99 wrote: